Projects

Direct printing of metal microstructures for industrial innovations (DMI2)

Project description

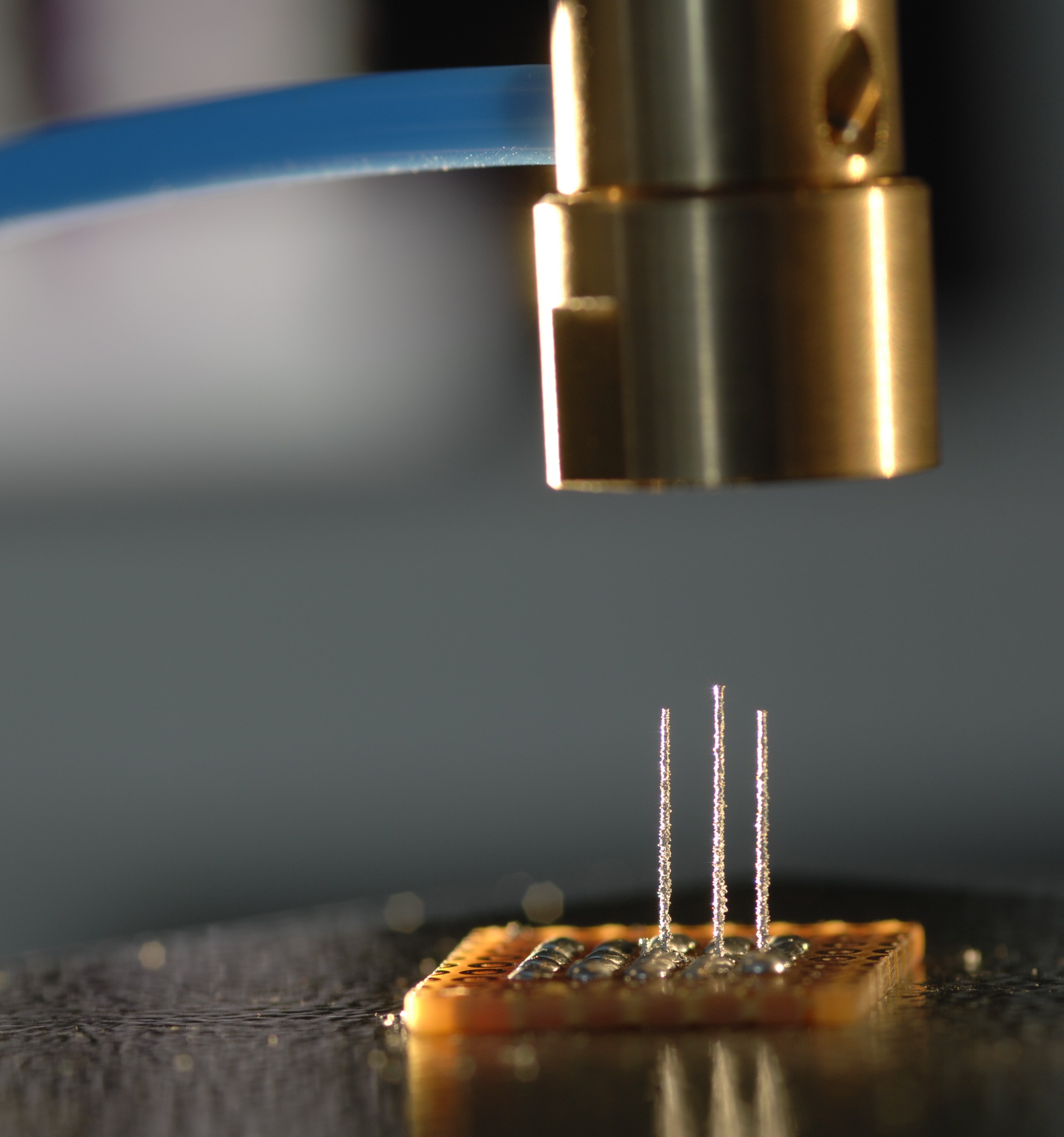

The DMI2 project conducts research and development in respect to the StarJet technology which was invented at IMTEK. This technology uses a pneumatically actuated printhead to dispense molten metals dropwise. A star-shaped nozzle chip, made from silicon, is used to form the droplets. The droplets can be ejected either individually in the “Drop-on-Demand” mode or in the “Continuous Mode” with frequencies up to 10 kHz.

The aim of the project is the reduction of droplet diameters down to 10 μm and the development of a high-temperature printhead which enables the printing of high-melting metals at up to 1000 °C. This enables the direct printing of metals such as aluminium or silver.

The potential of the technology is evaluated for different industrial applications which can profit from direct metallization techniques. Thereto, the StarJet-based printhead is integrated in a high-precision industrial printing platform.

Potential industrial applications include the direct metallization of solar cells, as well as the realization of three dimensional interconnections for microelectronics among others.

Start/End of project

01.10.2013 until 30.09.2016

Project manager

Dr. Peter Koltay (Prof. Dr. Roland Zengerle)

Contact person

Dr. Peter Koltay

Phone:+49 761 203-73240

Email:peter.koltay@imtek.uni-freiburg.de

Funding

BMBF

Keywords

Metall, Silizium & sonstige Halbleiter, Mikrodosierung, Aufbau- und Verbindungstechnik, Automatisierungstechnik & Verfahrenstechnik, Metalldosierung, Silizium, Halbleiter, Mikrodosierung, Verbindungstechnik, Automation, Prozessentwicklung, liquid metal, silicon and other semiconductors, microdosing, assembly and packaging, automation & process engineering