Projects

SmartLab2 - Forming of foils with already applied electronic components for the production of lab-on-a-chip test carriers with extended functionalities.

Project description

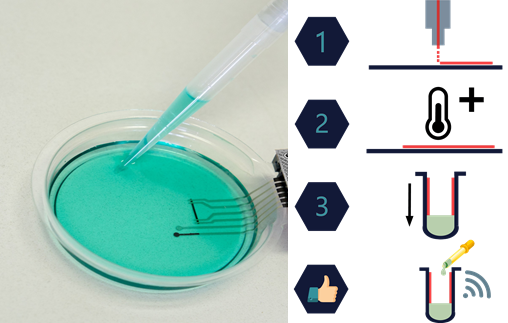

The aim of this project is to produce laboratory consumables from moulded plastic (e.g. Eppendorf tubes, on-site diagnostic test carriers) with integrated sensors (T-sensor, electrodes) as functional samples. The sensor technology should already be applied to the two-dimensional film substrate and only then be formed into a 3D structure, which significantly simplifies the application process of the sensor technology. By integrating sensor technology directly into the laboratory equipment, continuous monitoring of the sample and process steps is achieved with a high degree of accuracy. The fixed arrangement of the sensor technology replaces the manual assembly of these in the laboratory, which prevents incorrect assembly and increases the reproducibility of measurement results. The planned extension of the concept to multi-layer composites will further increase the functionality of the consumable (e.g. use in harsh environmental conditions, insertion of electrolysis cells). These aspects make a particular contribution to the quality assurance of laboratory analyses. In order to be able to pursue the task in a targeted manner, the forming process is considered in advance supported by a new simulation approach, which enables a particularly effective development process. To realise the project, established technologies (direct printing of sensors, microthermoforming of film substrates) are to be combined for the first time in order to make existing processes more efficient or to enable new product classes (smart laboratory consumable).

Start/End of project

01.11.2022 until 31.10.2024

Project manager

Philip Koch (Prof. Dr. Roland Zengerle)

Contact person

Philip Koch

Phone:+49 761 203-54018

Email:philip.koch@hahn-schickard.de

Partners

Accensors GmbH, Espelkamp

Koordinator, Entwickler und Hersteller von gedruckter Sensorik auf Foliensubstrat und Skalierungspartner für den 3D-Thermoformprozess zur Erstellung von sensorbasierten Probengefäßen. Espelkamp

OrelTech GmbH, Berlin

Entwicklung von speziellen Drucktinten zur Herstellung von Foliensensoren

SimpaTec Simulation & Technology Consulting GmbH, Aachen

Entwicklung der Simulationssoftware zur Verzugsberechnung des Sensorlayouts durch den 3D-Thermoformprozess

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V., Freiburg

Forschungseinrichtung, Erforschung des 3D-Thermoformprozesses von Foliensensoren

Funding

BMBF

Keywords

Lab-on-a-Chip / Sensorsysteme / Verformungssimulation / Simulation & Modellierung / Aufbau- und Verbindungstechnik